November 29th, 2018

Features of Goto Udon

- Mechanical Properties and Scanning Electron Microscopy -

Masaharu Yamada Dr.

Food Chemistry and Technology Laboratory

School of Advanced Engineering

Kogakuin University

1. Objectives

Goto Udon, Inaniwa Udon, and Sanuki Udon were boiled. They are major traditional white salted noodles in Japan. The boiled noodles were examined on mechanical properties using a materials testing machine. Also, dried and boiled noodles of the three kinds of samples were photographed using a scanning electron microscope (SEM). Based these observation results, discussed are the difference in the characteristics of the three kinds of dry noodles and boiled noodles.

2. Materials

Udon samples used are as follows:

(1) Goto Udon

Maker: Inukai Seimenjo

Crude protein: 9.4%

Manufacturing method: The dough is extended. Noodle strip is made by twisting and stretching motion. The noodle is very thin, therefore plant oil such as camellia oil is applied on the surface of noodles to avoid sticking between noodles.

(2)Inaniwa Udon

Maker: Sato Yosuke Shoten

Crude protein: 8.7%

Manufacturing method: The dough is extended. Noodle strip is made by twisting and stretching motion. The noodle is very thin, therefore dusting flour such as potato starch is applied on the surface of noodles to avoid sticking between noodles.

(3)Sanuki Udon

Maker: Kawada Seimen

Crude protein: 9.1%

Manufacturing method: The dough is kneaded and proofed to develop gluten. Then, the dough is thinly spread and cut with a knife.

3. Methods

As a materials testing machine, an EZ-Test (Shimadzu, Japan) was used. Shear tests were performed with 10 mm/min shear rate using a shear blade (aluminum flat plate; 3 mm thickness, tip of the blade is rounded). Measurements were carried out three times in each condition.

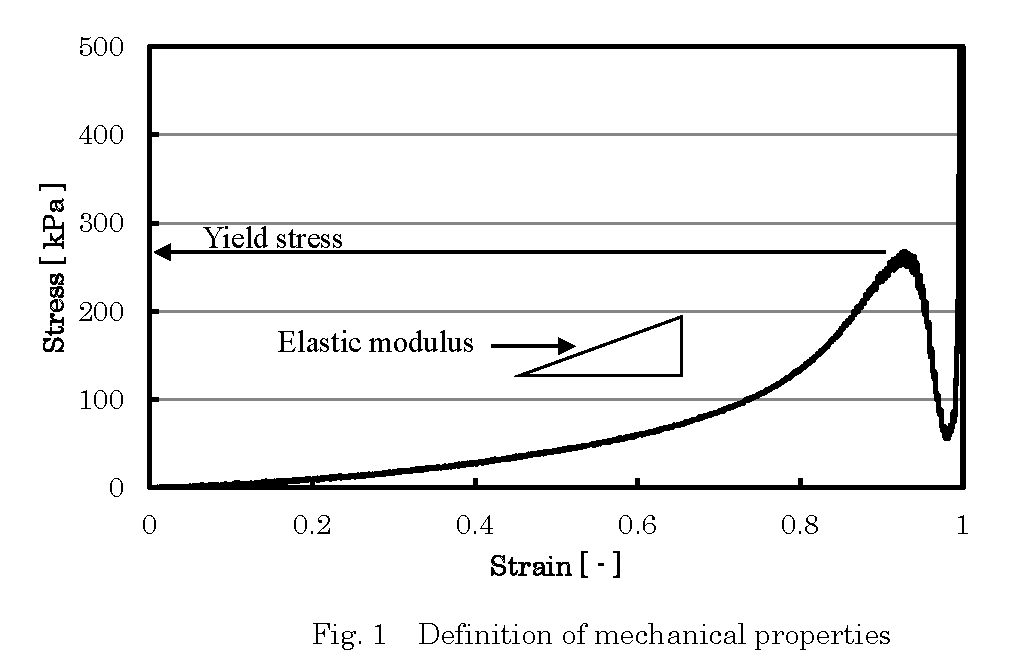

Based on the data, the load was converted to the load per unit area, that is, "stress" using the thickness of the blade (3 mm) and the thickness of the noodle, and the displacement was converted to “strain” by setting the maximum displacement amount as 1.

Converting data obtained to an Excel file, stress/strain relations were drawn.

In the stress/strain relations, yield stress and average elastic modulus between origin and yield point were adopted as indices of mechanical properties of boiled noodle.

The noodle samples coated with gold deposit were observed using SEM (JEOL JCM-6000, Japan).

4. Results

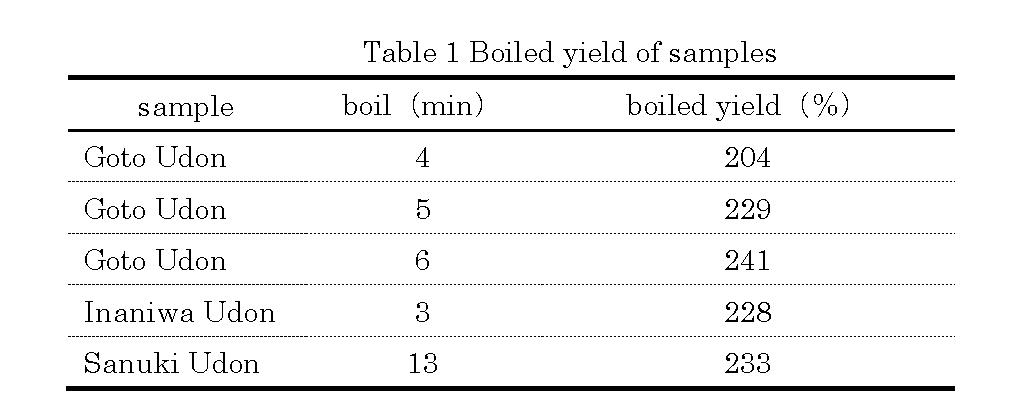

(1) Boiled yield

Each dry noodle was boiled during standard time labeled on the package. On Goto Udon, recommended boiling time labeled on the package is from 4 to 6 minutes. Therefore, Goto Udon was boiled during 4, 5, and 6 minutes respectively.

(2) Mechanical properties

(3) SEM photographs

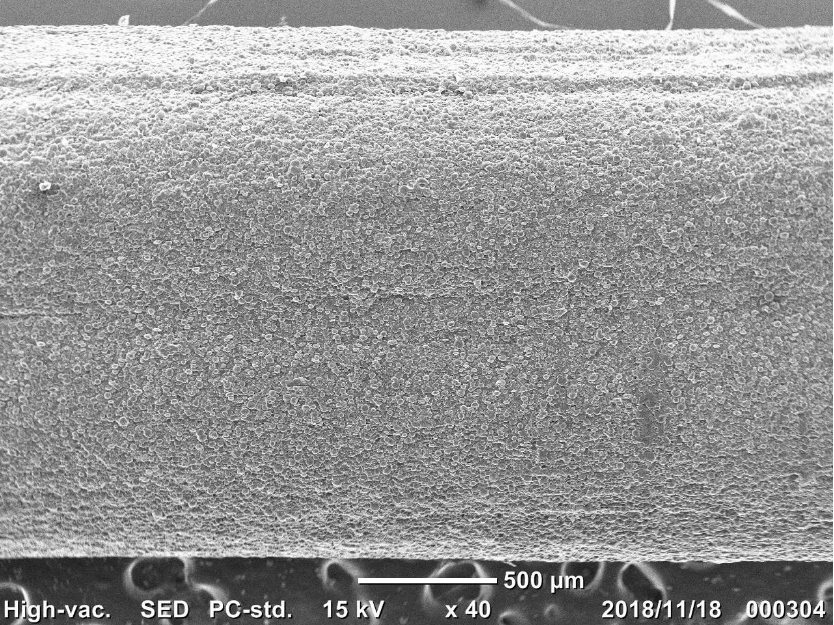

[1]Goto Udon

(White bar: 500 μm)

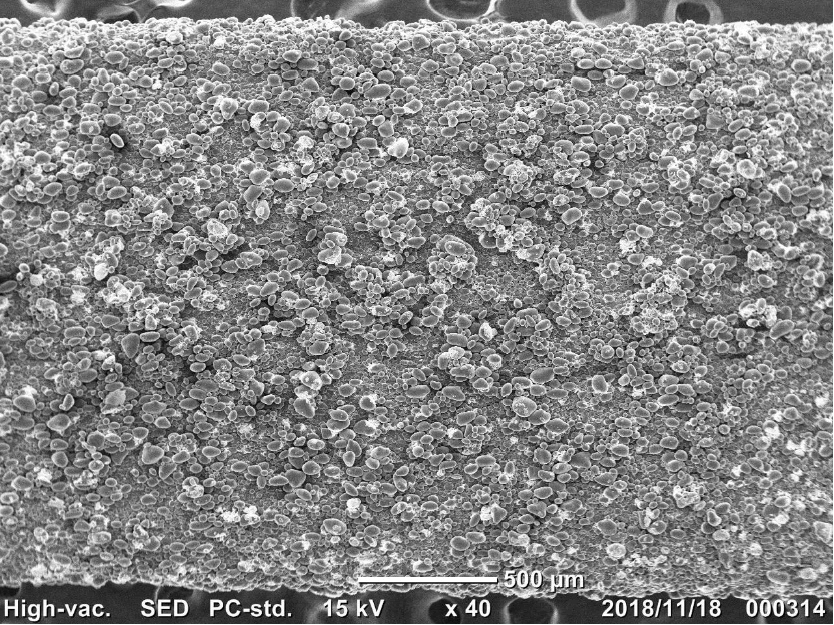

[2]Inaniwa Udon

(White bar: 500 μm)

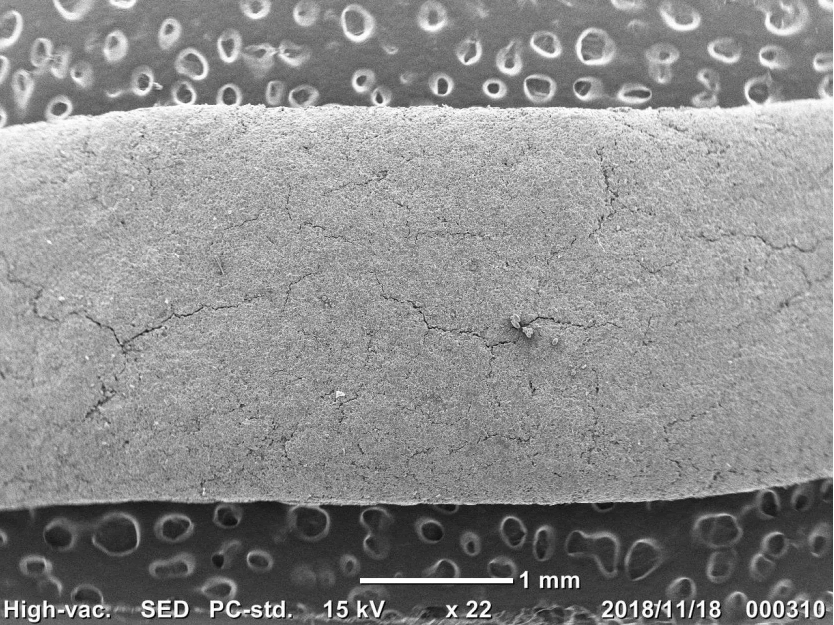

[3]Sanuki Udon

(White bar: 1 mm)

Photo 1 SEM photographs of dried noodles

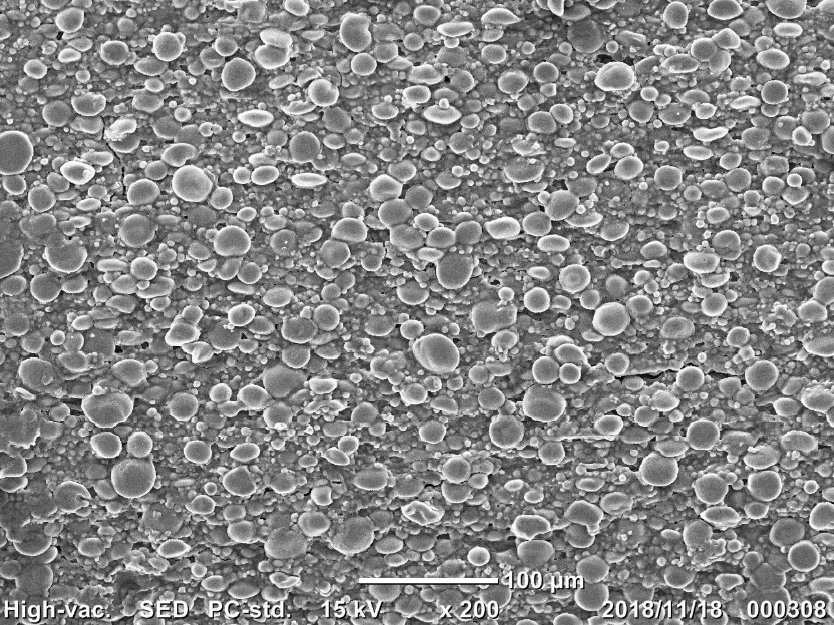

[1]Goto Udon

(White bar: 100 μm)

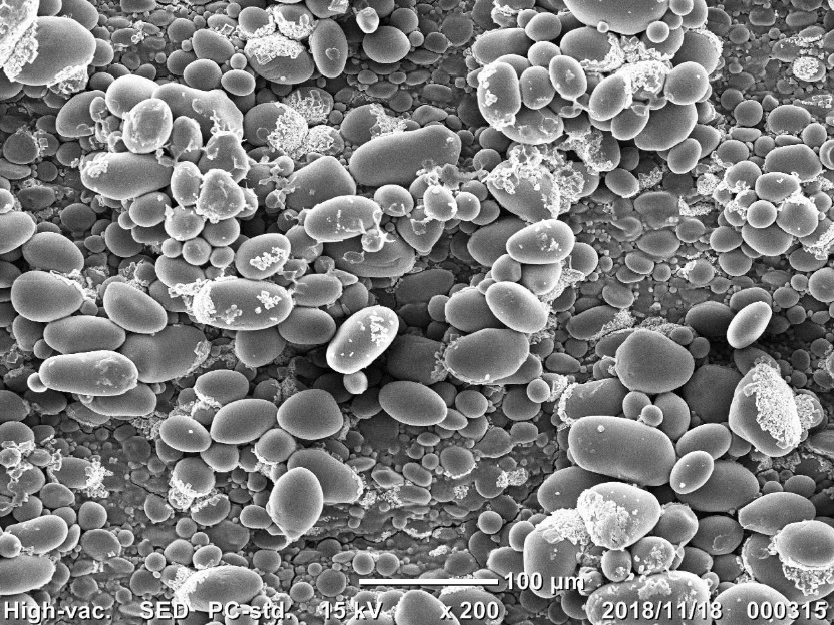

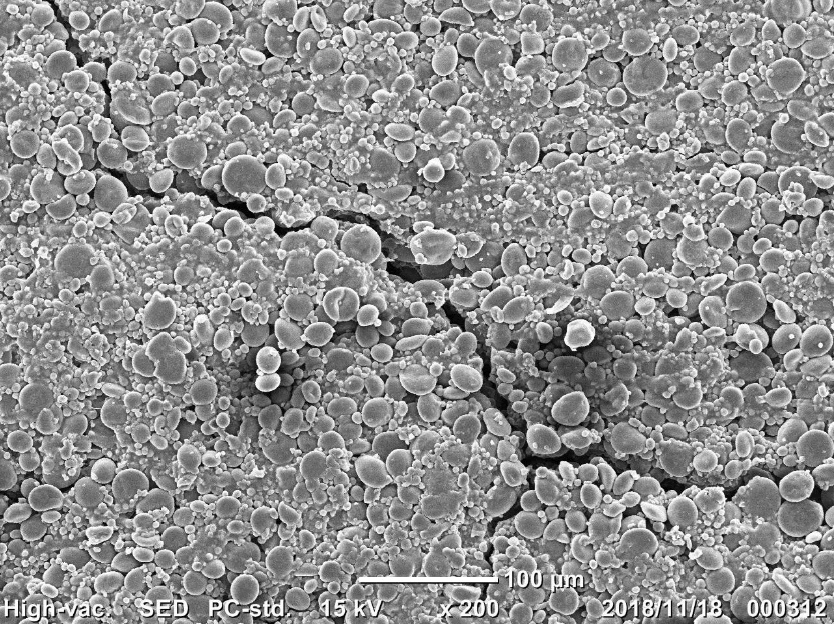

[2]Inaniwa Udon

(White bar: 100 μm)

[3]Sanuki Udon

(White bar: 100 μm)

Photo 2 SEM photographs of dried noodles

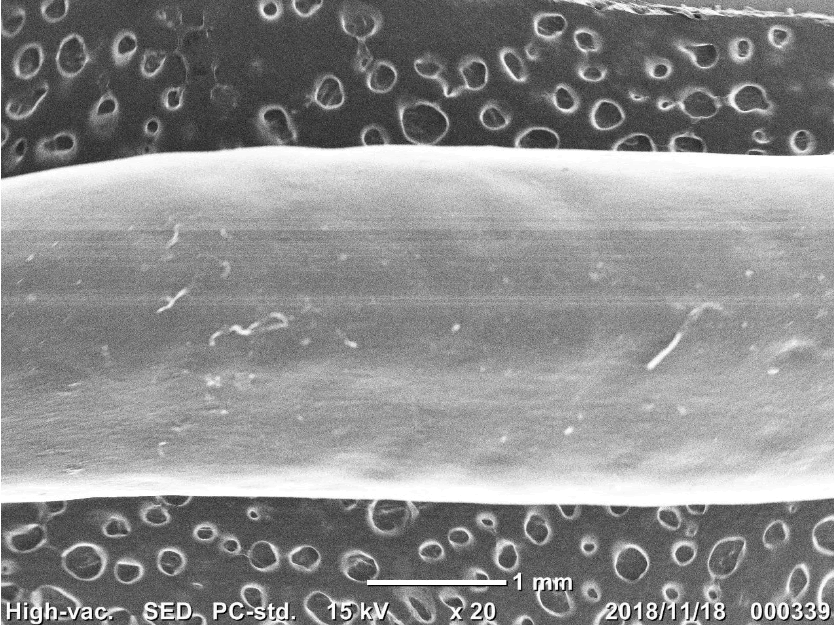

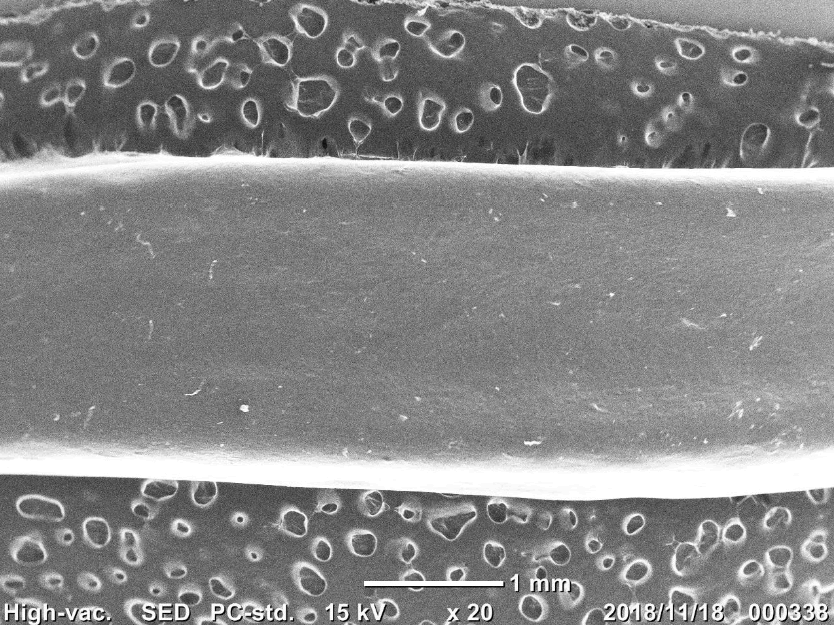

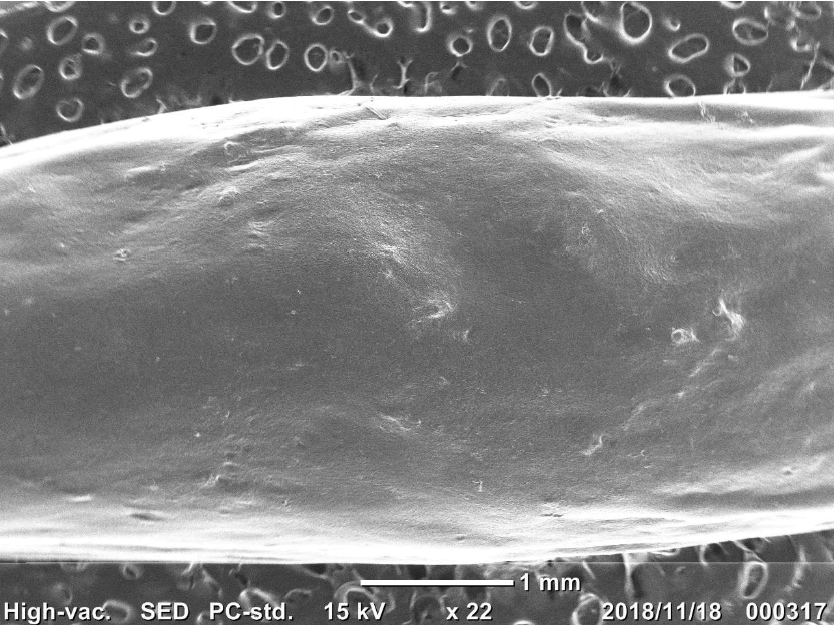

[1]Goto Udon (4 min boiled)

(White bar: 1 mm)

[2]Inaniwa Udon (3 min boiled)

(White bar: 1 mm)

[3]Sanuki Udon (13 min boiled)

(White bar: 1 mm)

Photo 3 SEM photographs of boiled noodles

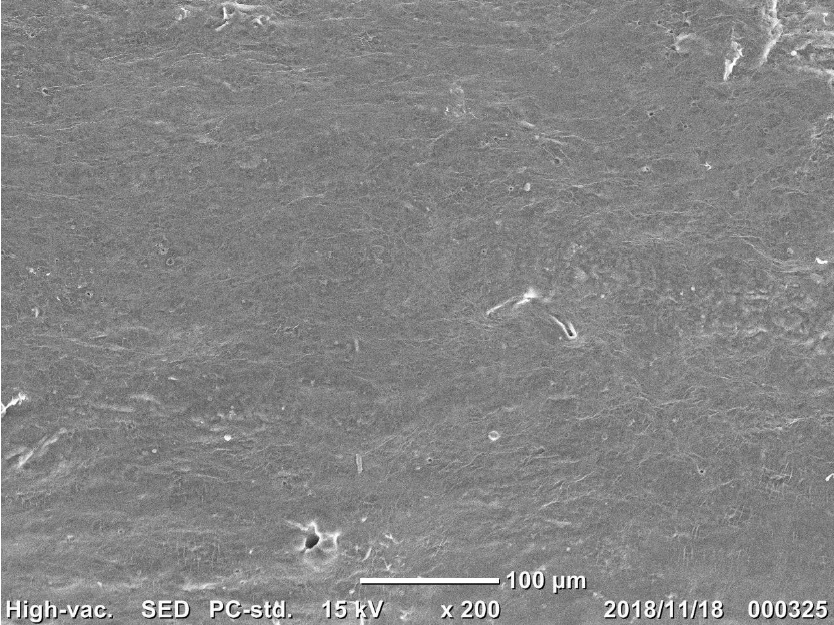

[1]Goto Udon(4 min boiled)

(White bar: 100 μm)

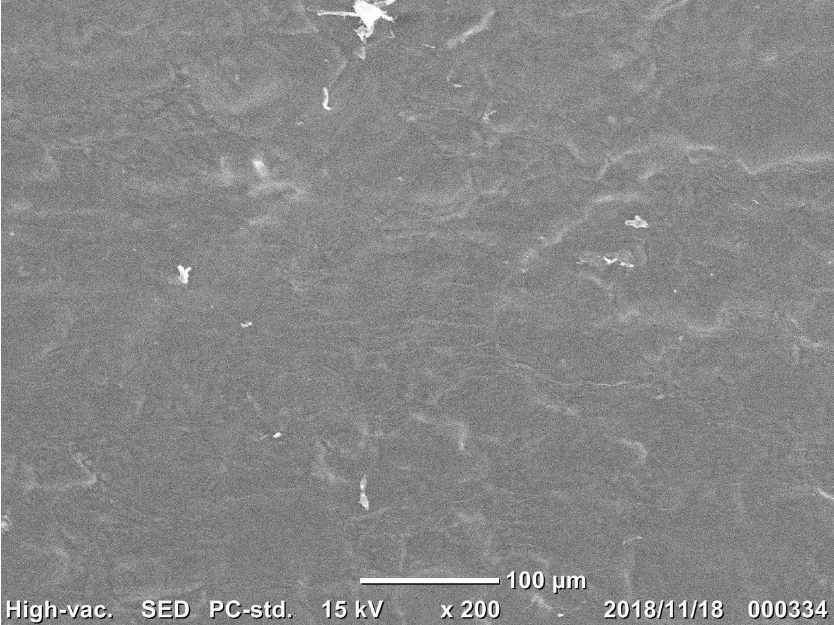

[2]Inaniwa Udon (3 min boiled)

(White bar: 100 μm)

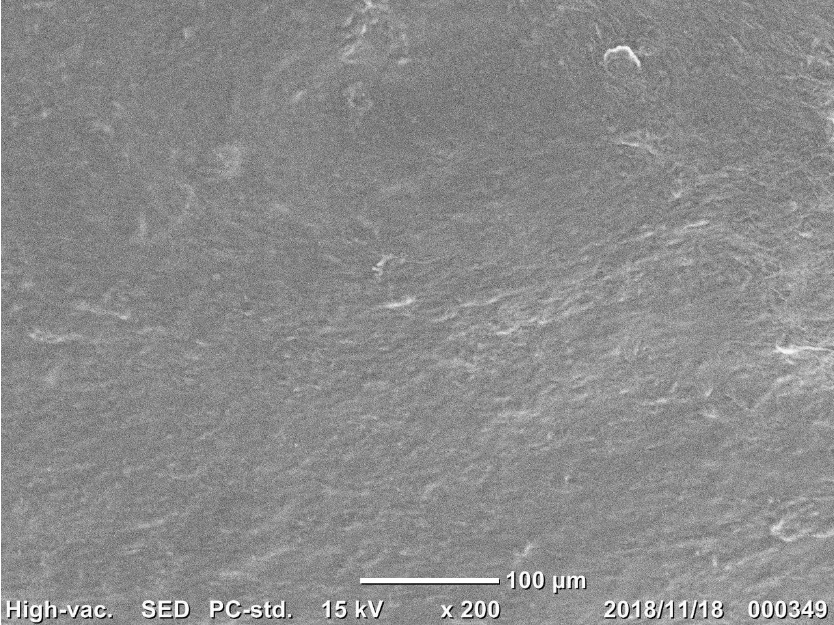

[3]Sanuki Udon (13 min boiled)

(White bar: 100 μm)

Photo 3 SEM photographs of boiled noodles

5. Discussion

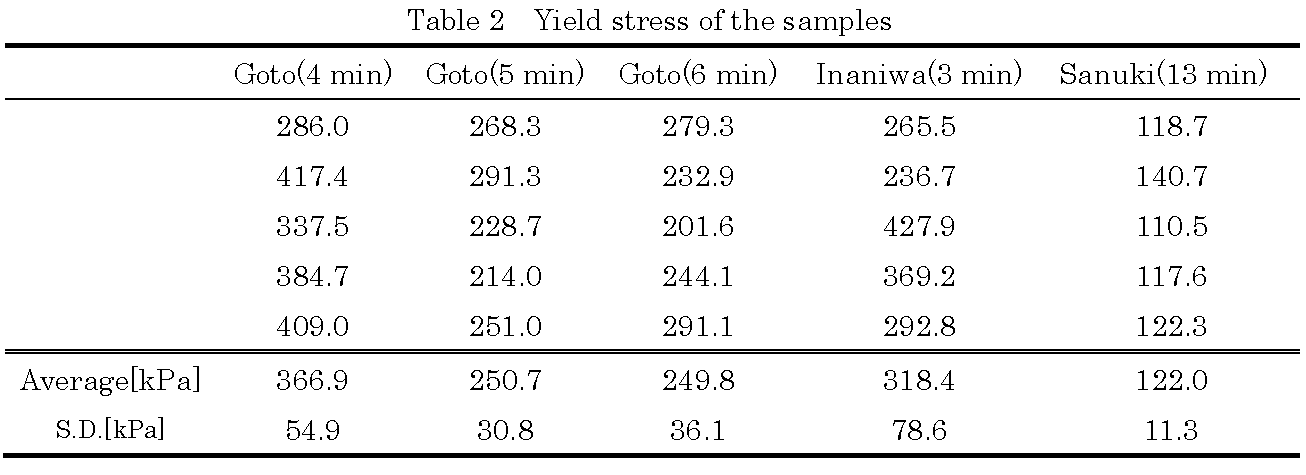

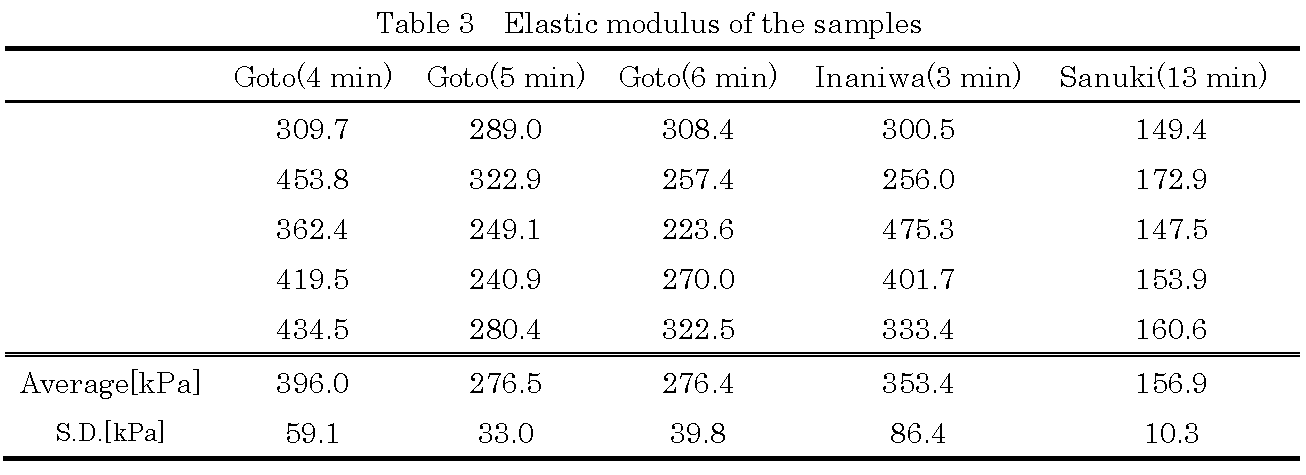

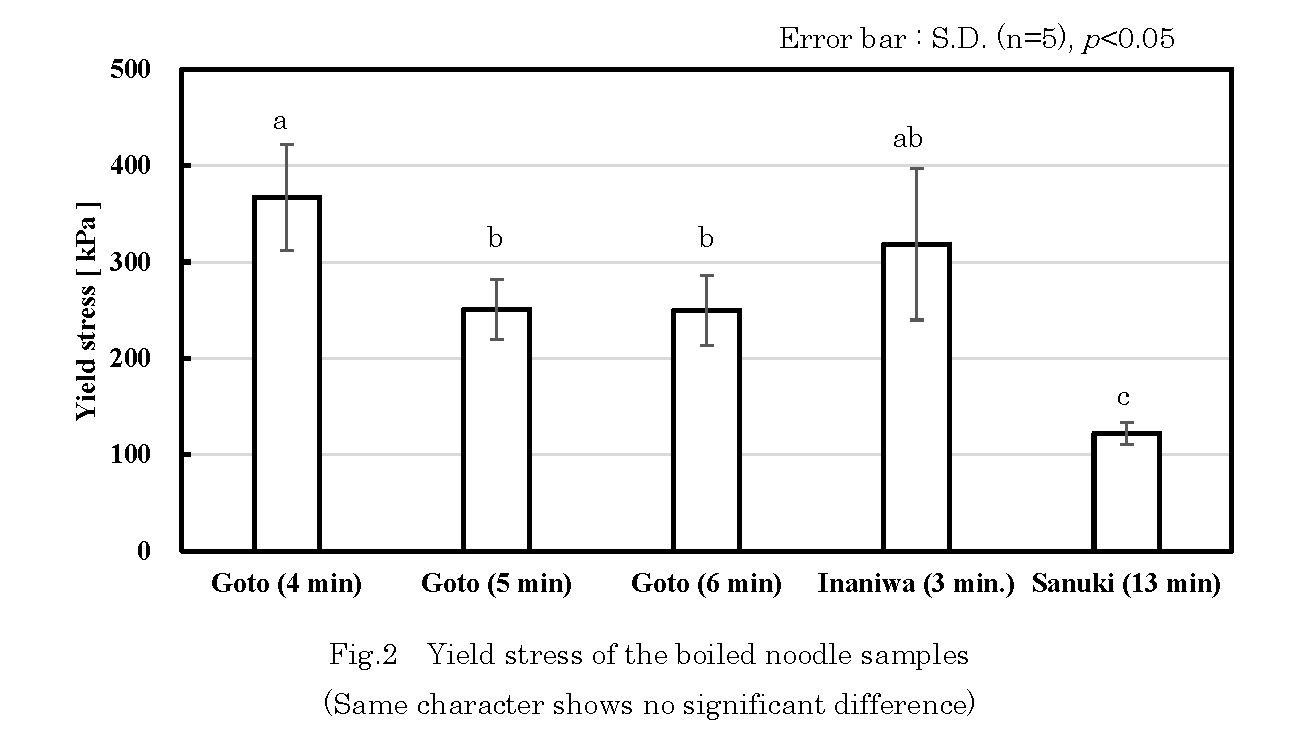

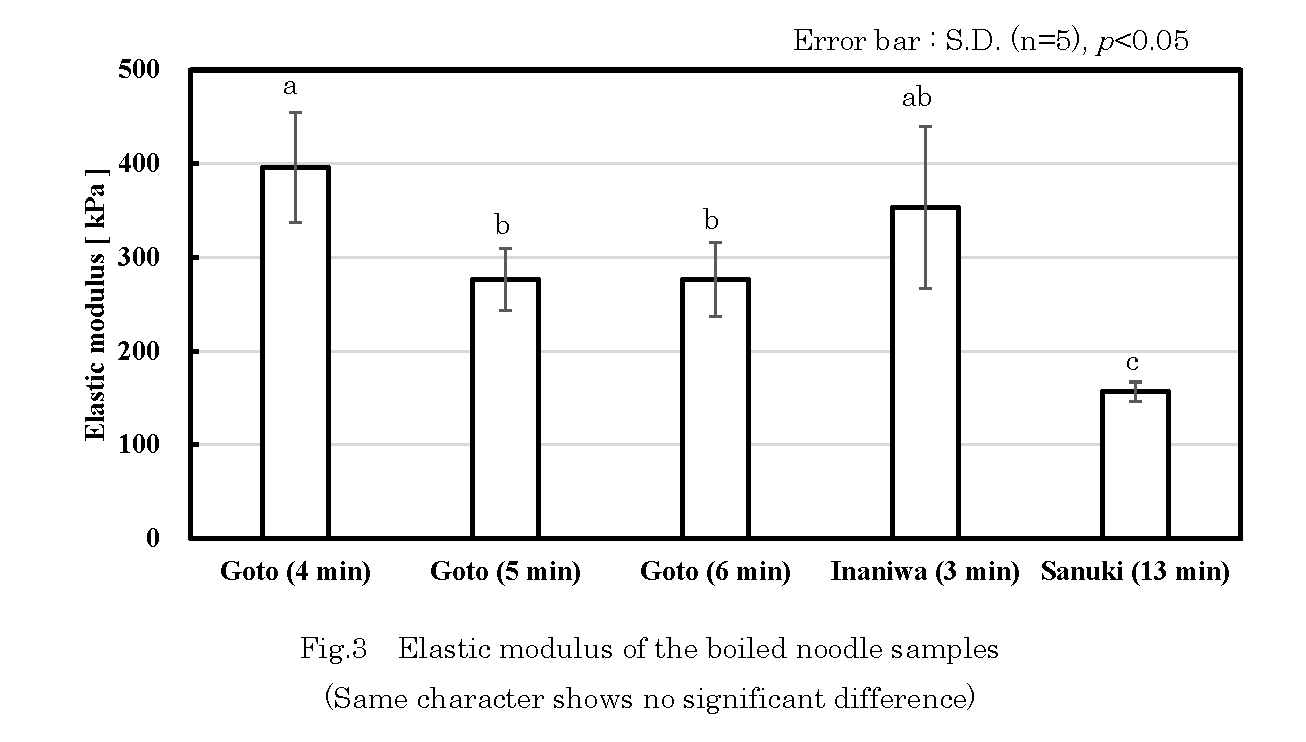

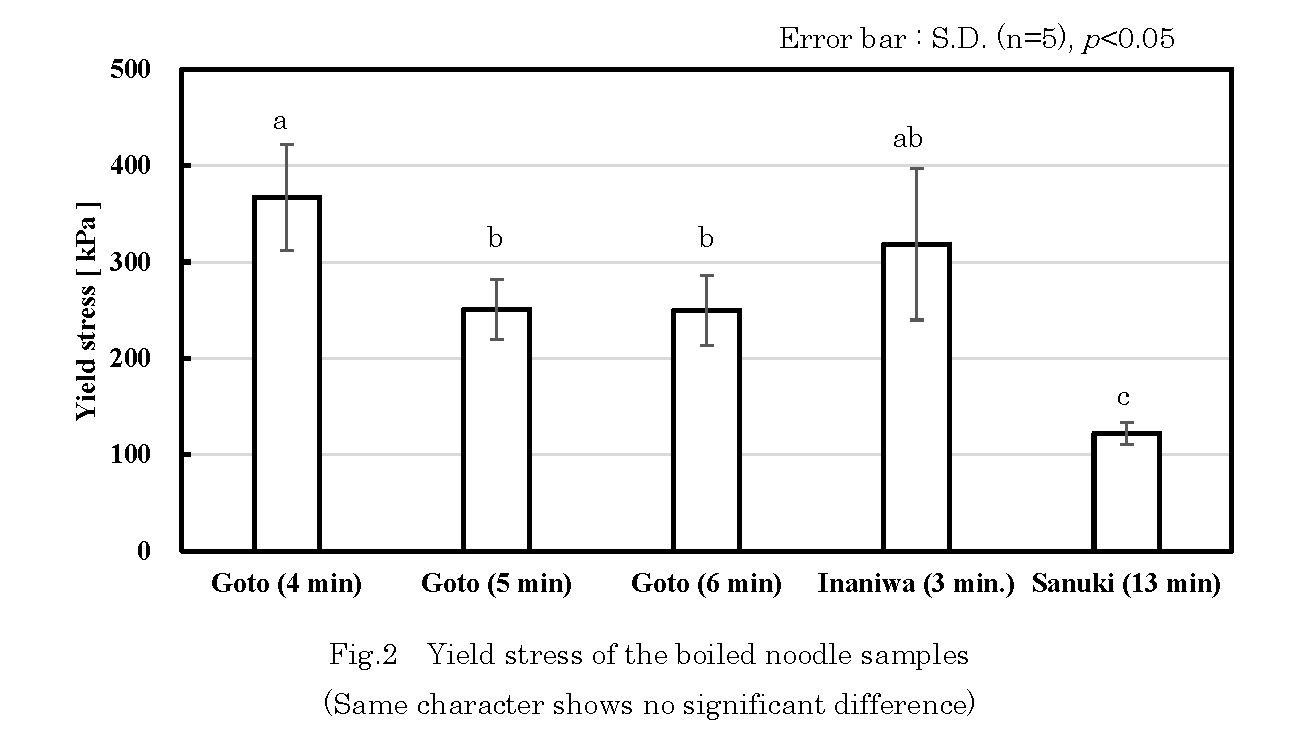

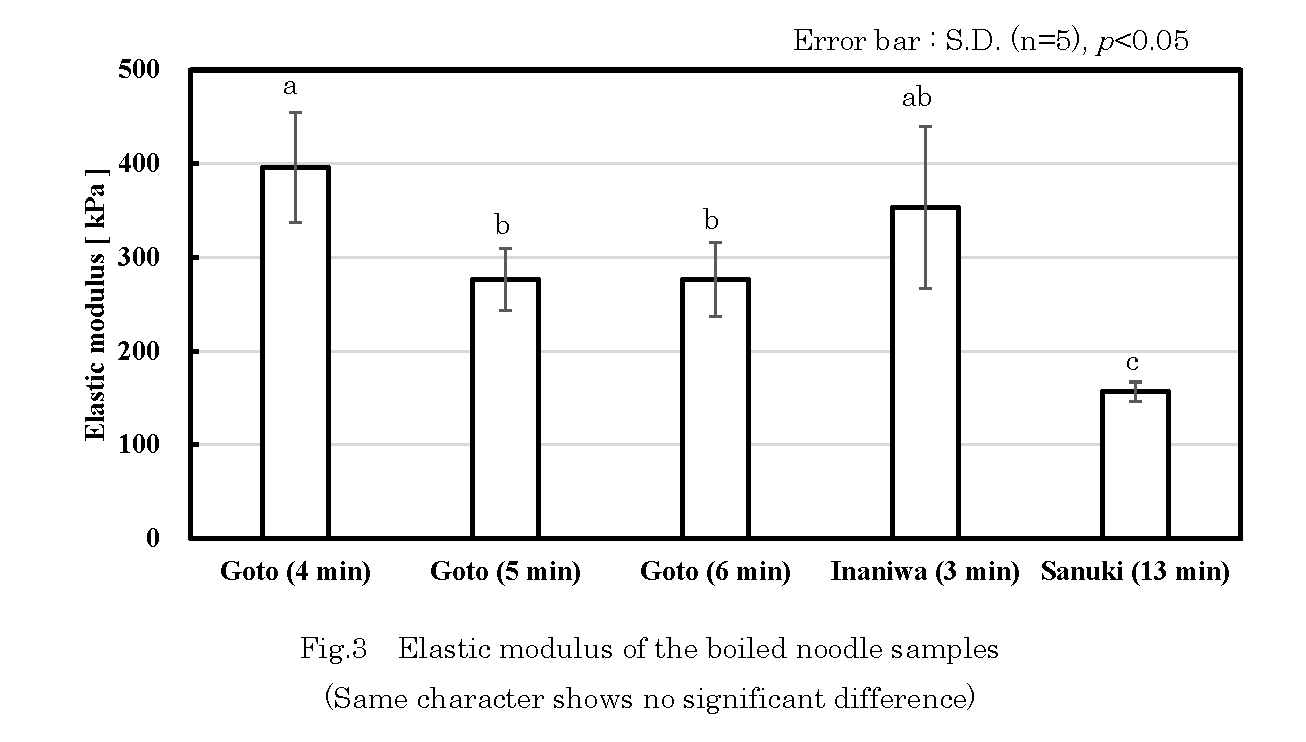

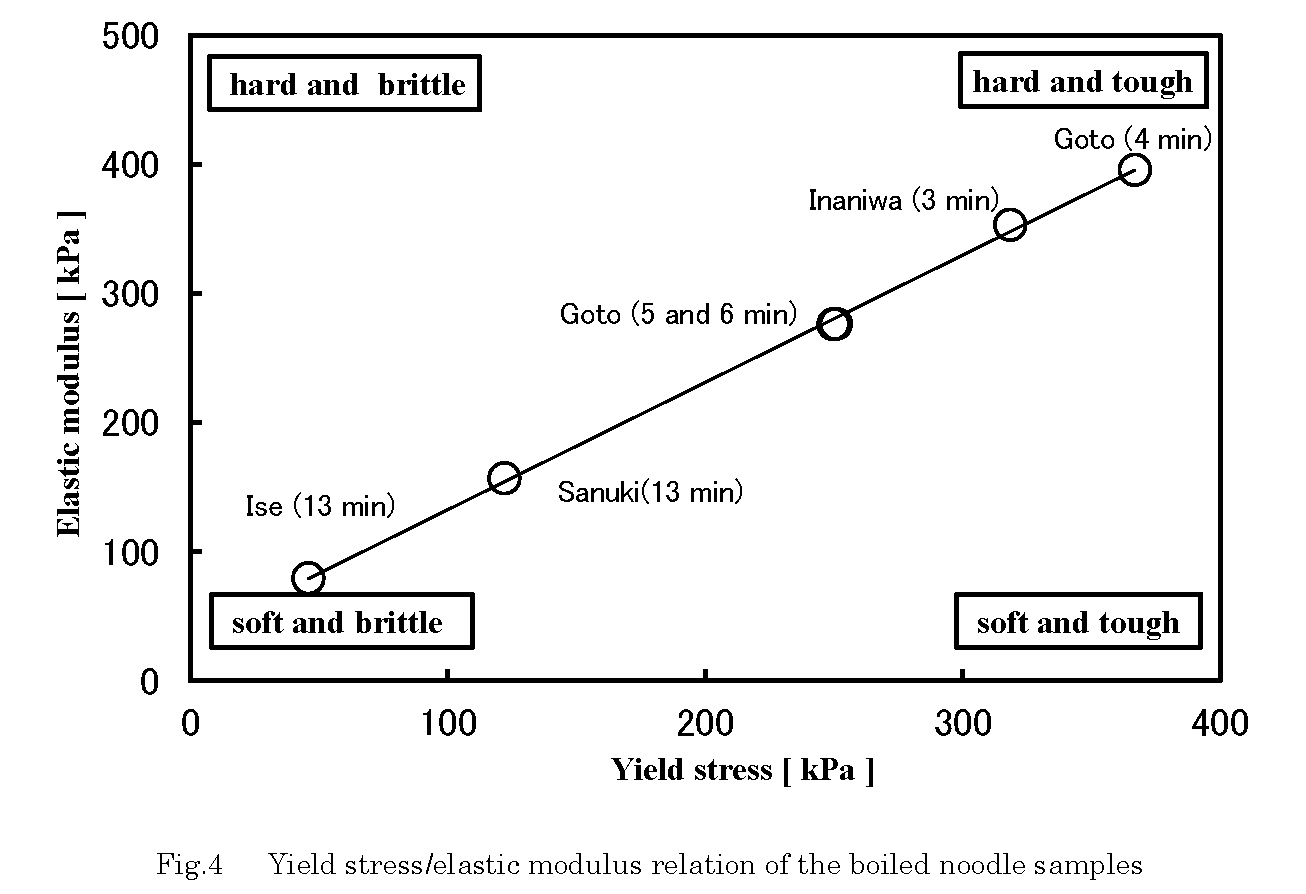

(1) Fig.2 and 3 show yield stress and elastic modulus of the boiled noodles respectively. On “a”, ”b”, and “c”, same character means no significant difference (P<0.05), and different characters mean significant difference (P<0.05). Goto Udon (4 min boiled) and Inaniwa Udon show high yield stresses, but there is no significant difference. Sanuki Udon is significantly lower than the other Udons samples.

(2) Yield stress and elastic modulus of Goto Udons (5 and 6 min boiled) are significantly lower than that of Goto Udon (4min boiled). However, there is no significant difference between Goto Udons (5 and 6 min boiled) and Inaniwa Udon.

(3) Generally, there are four eating texture: “hard and brittle”, ”hard and tough”, ”soft and brittle”, ”soft and tough”. The term “hard” and ”soft” are related to elasticity, and “brittle” and ”tough” are related yield stress.

Thus, yield stress/elastic modulus relation is drawn. Fig.4 shows the yield stress/elastic modulus relation of the samples. In this figure, Ise Udon datum obtained in another test is plotted.

In this figure, the upper right area shows hard and tough properties, and the lower left area shows soft and brittle properties. Interestingly, Fig.4 shows a linear relation in all of the data. There are no extremely “hard and brittle” samples and “soft and tough” samples, because all of the Udon samples are made from same raw materials: wheat flour, water, and salt.

Goto Udon (4 min boiled) is the most “hard and tough” sample. The properties of “hard and tough” texture might be equal to “Koshi” which is a traditional sensory term in Japanese noodles.

6. Summary

(1) Goto Udon (4 min boiled) shows elastic modulus and yield stress comparable to Inaniwa Udon.

(2) Sanuki Udon is apparently lower than Goto Udon and Inaniwa Udon in Elastic modulus and yield stress.

(3) Goto Udon (4 min boiled) is the most “hard and tough” sample. The properties of “hard and tough” texture might be equal to “Koshi” which is a traditional sensory term in Japanese noodles.

(4) In Inaniwa Udon, potato starch is applied on the surface of noodles to avoid sticking between noodles.